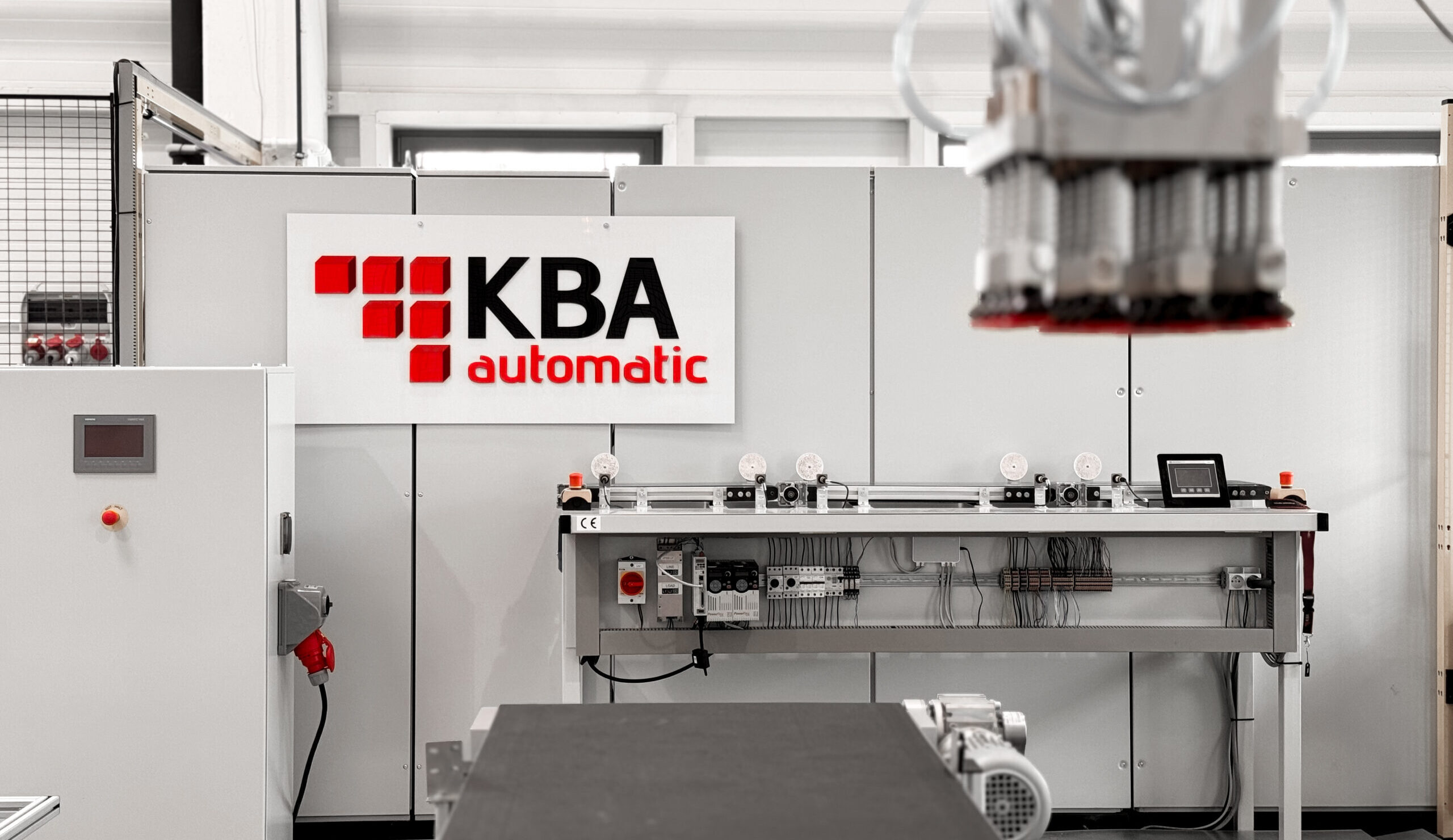

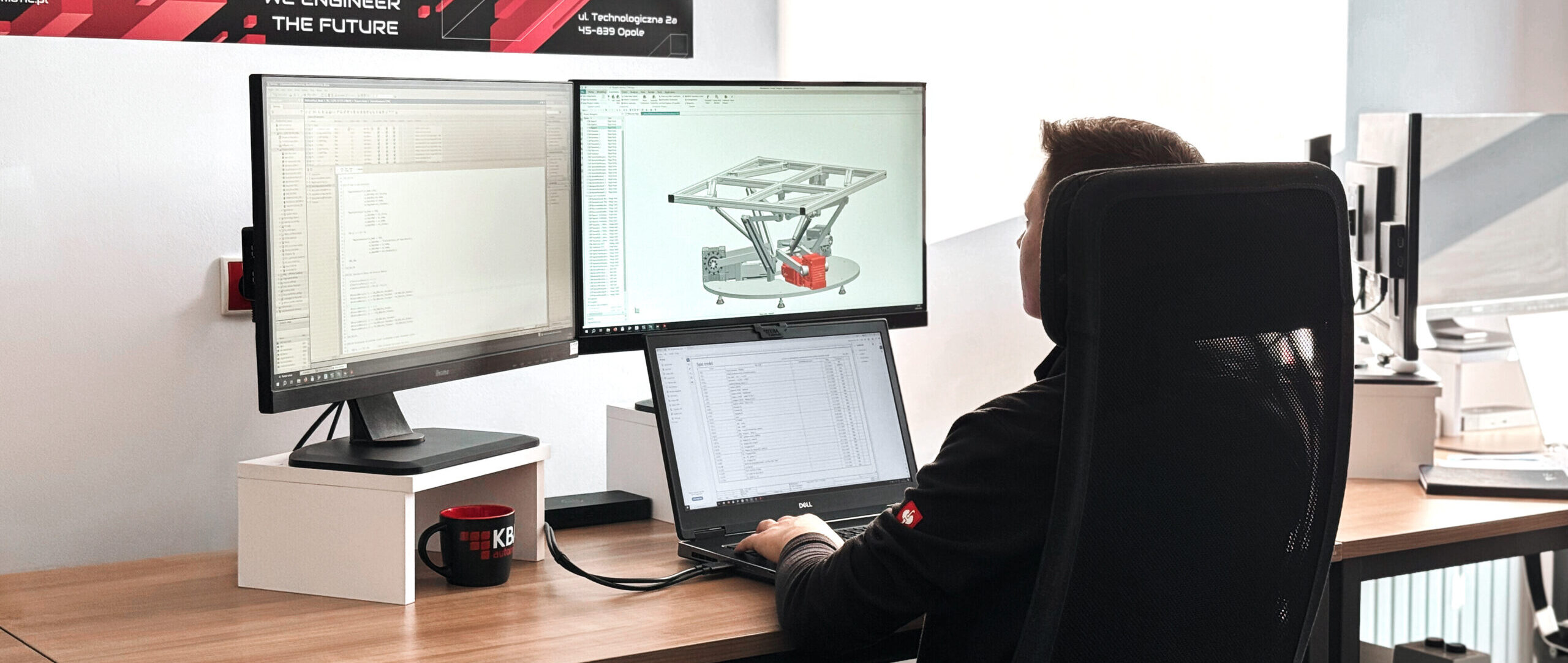

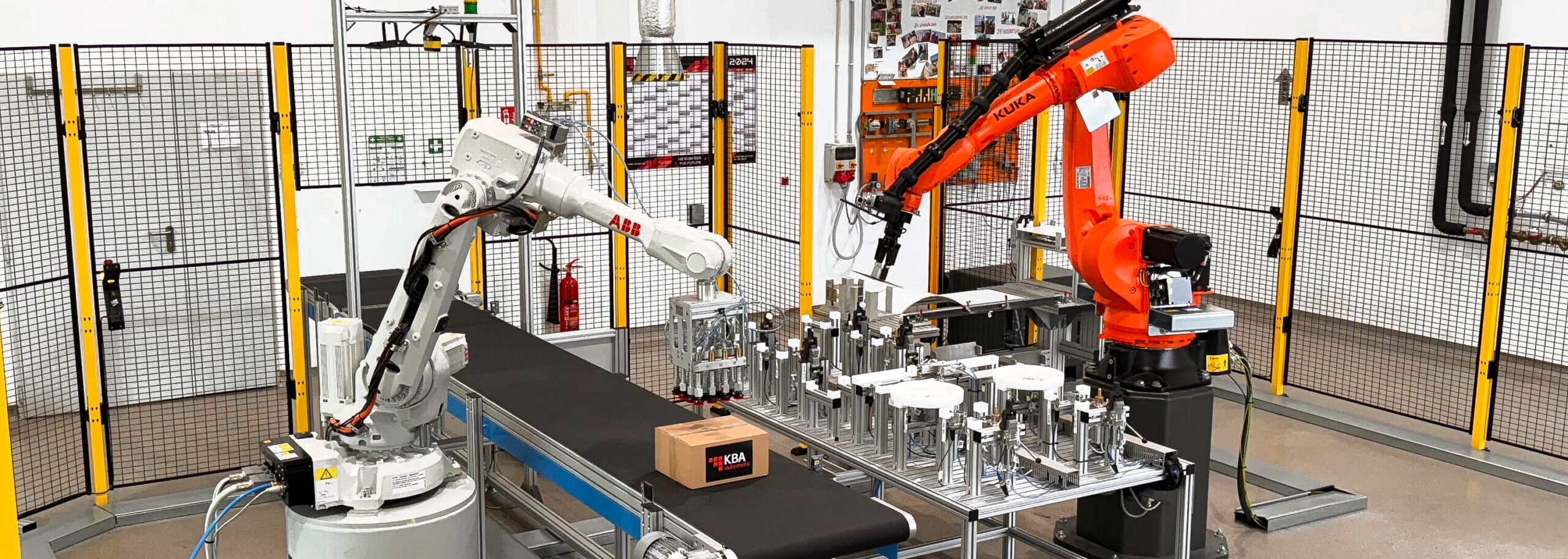

Every project completed is proof of our professionalism, innovation and reliability.

Nothing is impossible with KBA AUTOMATIC!

Our priority is gaining knowledge and applying it in every aspect of our work. We believe that earned experience acquired, constant development and inquisitiveness are key factors to growth and success.

We are convinced that to achieve true success, one has to leave their comfort zone and take on challenges.

It’s the boldness that lets us go beyond those limits, break

the status quo and make innovative decisions as well as strive for unconventional solutions to professionally fulfil complex obligations.

We see changes as a chances to develop and evolve. We stay remain flexible and open in the face of challenges and changing market dynamics. Using our ability to adapt, we deal with complex problems with creativity and

self-confidence. It i’s on this foundation that we build our expertise on.